| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

AHP PLASTİK MAK. SAN. VE TİC. LTD. ŞTİ.

No.78 Block A Perlavista Bld. / Beylikdüzü / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 872 5270

|

Hall: 1A

Stand: 1A-04

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

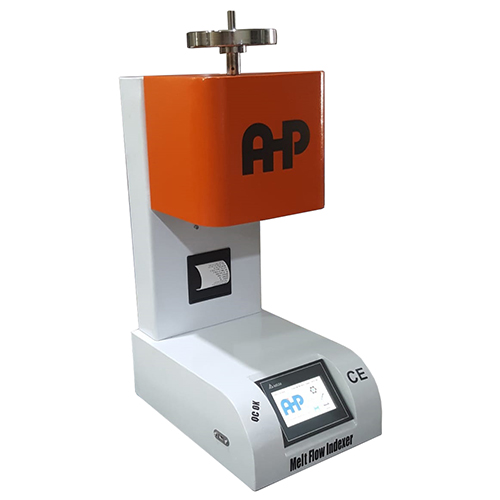

AHP PLASTIK MAKINA is manufacturer of Quality Control Testing Equipment for plastic raw materials and finished products such as pipes, fittings, valves, plastic tanks, cables, profiles, geomembranes, geo textiles, geo synthetics, films, shrink films, shoes, textiles, .

All Sectors, Automotive, Cables, Construction Insulation, Corrugated Pipes, Electro Technology IEC, Electrofusion Fittings, Film, Food, Footwear, Geo-Textiles, Geomembrane, HDPE Fittings, HDPE Gas Pipes, HDPE Valves, HDPE Water Pipes, Irrigation Pipes, Job Safety, Medical, Packaging, Pallets, PEX Pipes, Plastic Raw Materials, Plastic Tanks, PVC Fittings, PVC Pipes, PVC Valves, Synthetic Leather, Textiles, UPVC Profile

According to ASTM D3895 ISO11357 EN728 ASTM D3418 Up to 500C Including standard Tin, Ind pellets for calibration checkout 400pcs of aluminium pans Software CD (windows based software including Report out to WORD) N2 and O2 rotameter mass flow controller Hoses and connectors Software also has data export to advantage Software for analysis DSC measuring cell according to the heat flux principle Temperature sensors for control & sample temperature Connection for Purge gas flow to the sample for 2 gas types Temperature accuracy 0.1 C Sensitivity: 3.6 to 4.0 μV/mW Sensor Time constant: 2.5 s Calorimeter accuracy of ± 2% Calorimetric precision of ± 0.5% or better Two connections for purge gas-Inlet to the sample & 1 connection for cooling air

According to ISO 6259 Capacity maximum 20KN Load resolution 1/10000 Displacement accuracy ≤0.5% Speed range 0.01-200 mm/min Cross head travel 900 mm (without grips) German ball screws Calculation of yield, UT, elongation at break and all other tensile and compression parameters by software Timing belt force transmission system for low noise Hard chrome guide shafts Overload protection Travel limit switches Manual high speed up and down detachable handkey Distance between two columns 350mm Power consumption about 1000W Windows based software Power 220V-50Hz Training video Report in MS EXCEL Easy calibration by operator

According to ISO 1167 , ASTM D1598 and ASTM D 1599 European pump, sensors and valves 19″ display (On request) Report out in WORD Manual charge and discharge Automatic pressure control Pressure rate control Water circulation system Digital temperature controller Airless system Maximum accuracy, a long service life and a user-friendly system, combined with flexibility High-precision pressure regulation, selectively regulated input pressure in each Line All metal components that come in contact with the medium is brass ans SS304 Quick system calibration easily by the operator and calibration data saved in the controller modules Convenient operation, evaluation of results and clear visualization via Labview and windows based software Operator access to all important settings from the front panel Each station can be individually isolated from the supply pressure for service purposes PLC based control of the pressure channels Pressure gauge for checking each line actual pressure High-quality unit components guarantee long service life Along with AHP data logging software quarantine keeping of data in power break cases Ramp control capabilities for each line pressure European components of valves, sensors and pump Including high pressure accumulators

According to below standard: ASTM D4329 Standard Practice for Fluorescent UV Exposure of Plastics ASTM D4587 Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coatings ASTM D4799 Standard Test Method for Accelerated Weathering Test Conditions and Procedures for Bituminous Materials (Fluorescent UV and Condensation Method) ASTM D5208 Standard Practice for Operating Fluorescent Ultraviolet (UV) and Condensation Apparatus for Exposure of Photodegradable Plastics ASTM G151 Standard Practice for Exposing Nonmetallic Materials in Accelerated Test Devices that Use Laboratory Light Sources ASTM G154 Standard Practice for Operating Fluorescent Light Apparatus for UV Exposure of Nonmetallic Materials DIN EN 12224 Geotextiles and geotextile-related products Determination of the resistance to weathering DIN EN 1297 Flexible sheets for waterproofing Bitumen, plastic, and rubber sheets for roofing Method of artificial ageing by long term exposure to the combination of UV-radiation, elevated temperature and water DIN EN 13523-10 Coil coated metals Test methods Part 10: Resistance to fluorescent UV light and water condensation DIN EN ISO 4892-1 Plastics Methods of exposure to laboratory light sources Part 1: General guidance EN 927-6 Paints and varnishes Coating materials and coating systems for exterior wood Part 6: Exposure of wood coatings to artificial weathering using fluorescent UV and water ISO 11997-2 Paints and varnishes Determination of resistance to cyclic corrosion conditions Part 2: Wet (salt fog)/dry/humidity/UV light ISO 16474-3 Paints and varnishes Methods of exposure to laboratory light sources Part 3: Fluorescent UV lamps ISO 4892-3 Plastics Methods of exposure to laboratory light sources Part 3: Fluorescent UV-lamps EN 1062-4 Paints and varnishes Coating materials and coating systems for exterior masonry Part 4: Preconditioning of exterior coatings to UV radiation and water in apparatus SAE J2020 Accelerated Exposure of Automotive Exterior Materials Using a Fluorescent UV and Condensation Apparatus Proven performance matches or exceeds other brands Digital timer, UV and temp controller on the panel and fully programmed control using Windows based software USB data connection to PC including software Unsurpassed safety compliance Recirculating spray water option Plus many other exclusive user-friendly features Fluorescent UV lamps (8) 40 W (UVA-340, UVB-313, UVA-351) all are based on customer request Black Panel Temperature (BPT) calibration sensor Over-temperature shutoff Specimen easy holder Irradiance calibration ports Ergonomically designed specimen retaining rings It has functions of UV, Spray, Temperature control and Humidity control

The melt pump is driven by servo motor Equipped with manual plate nitride treated screen changer of high hardness and wear resistance High precise melt pressure sensor provides an accurate melt pressure Computer included and machine has 6 ceramic heating zones Eqquipped with 2 melt pressure sensor and swiss made melt pump Software is based on LABVIEW and reporting is on MS WORD

According to standards ISO 16770 and DVS 2203-4 Number of stations as customer request 10 inch touch display (as per customer request) Report as MS EXCEL file 100 l of tank capacity Circulation system for bath Sample elevator system SS304 bath Temperature up to 95 C Load ranges as request Fine adjust of force by lever mechanism Number of loadcells as per customer request (one for all stations or one per each station)

Increased pressure influences all physical changes and chemical reactions in which a change in volume occurs. Study of thermal effects under pressure increase the reaction rate or shift evaporation to higher temperature. High pressure differential scanning calorimetry allows you to measure samples under precisely defined atmospheres at pressures of up to 3.4 MPa as a function of temperature or time. Higher pressures and temperatures accelerate chemical reactions and shorten analysis times. Increased pressure is a factor that influences all physical changes and chemical reactions in which a change in volume occurs. For material testing, process development or quality control there is often no alternative to DSC measurements under pressure. Increased pressure suppresses vaporization and shifts the effect to higher temperatures. The high pressure differential scanning calorimetry (HPDSC) is an excellent instrument for studying the influence of pressure and atmosphere on a sample or for separating an effect that is overlapped by vaporization. As per ASTM D 5885 Suitable for testing of geomembranes, geotextiles Simulates real process condition of materials Reduce of analysis time comparing normal DSC Pressure range up to 3.5 MPa High pressure causes higher gas concentration during testing Accuracy +-0.2K Reproducibility +-0.1K Heating rate up to 50K/min SS304 pressure vessel Including standard Tin, Ind pellets for calibration checkout 200pcs of aluminum pans RS485-usb converter Heating rate up to 50 C/min Automatic cycle control Automatic gas valves Making report templates as operator settings Data output for universal analyzer software like TA High sensitivity Calibration software Calculation of Onset points-Max-Min points-Slope analysis- Graph analysis Data processing DSC-Temp-Time data saving Software CD User manual Capable of measuring OIT-DSC Temperature accuracy 0.1C Usable for OIT measurement and melting point N2 and O2 pressure regulator Power 220V-50Hz Training video

Oven diameter 600mm Max Temperature 300C Max rotational speed 30rpm Mold as per customer request Pyrex glass window to see inside oven Mold material aluminum and pyrex Control from panel and PC using USB port PC in optional 9-Step programmable software Telescopic door Aperture on oven for IR temperature measurement of mold surface Sliding mold movement into oven Adjustable arm for laptop placement Control panel based on PLC

Load Weight: 5N,10N Roll Dim: Diameter 150mm Length 460mm Rotation Speed 40rpm Moving Distance of the Holder: 4.2mm each rotation

No represented companies found.

- AHP

TR

TR