| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

GNEUSS KUNSTSTOFFTECHNIK GMBH

Mönichhusen 42 / North Rhine Westfalia / Bad Oeynhausen / GERMANY

|

Contact Info: +49 5731 53070

|

Hall: 11A

Stand: 11A-143B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

With 40 years of experience and over 100 patents, Gneuss is a supplier of innovative solutions for the recycling industry. The patented MRS extrusion technology offers new possibilities regarding the efficient devolatilization of PET, PS, nylon or polyolefins. In combination with Gneuss process constant and fully automatic screen changers and high-quality pressure and temperature sensors, efficient processing of highly contaminated materials becomes possible. The fully automatic Rotary Filtration Systems and screen changers operate continuously and provide constant pressure with or without back-flushing. The new series of turnkey OMNI recycling machines is customizable for handling demanding applications and achieving the highest quality requirements.

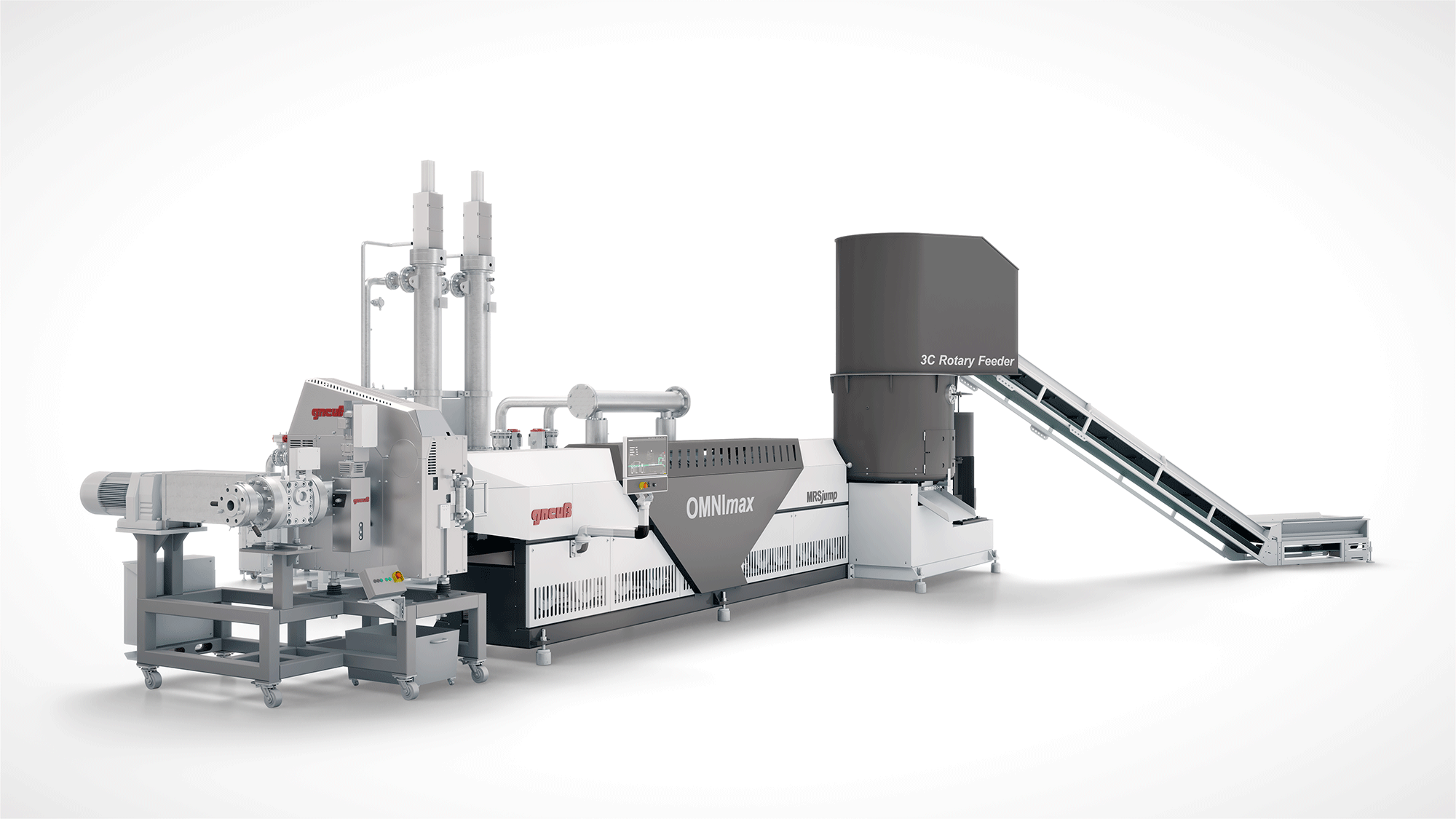

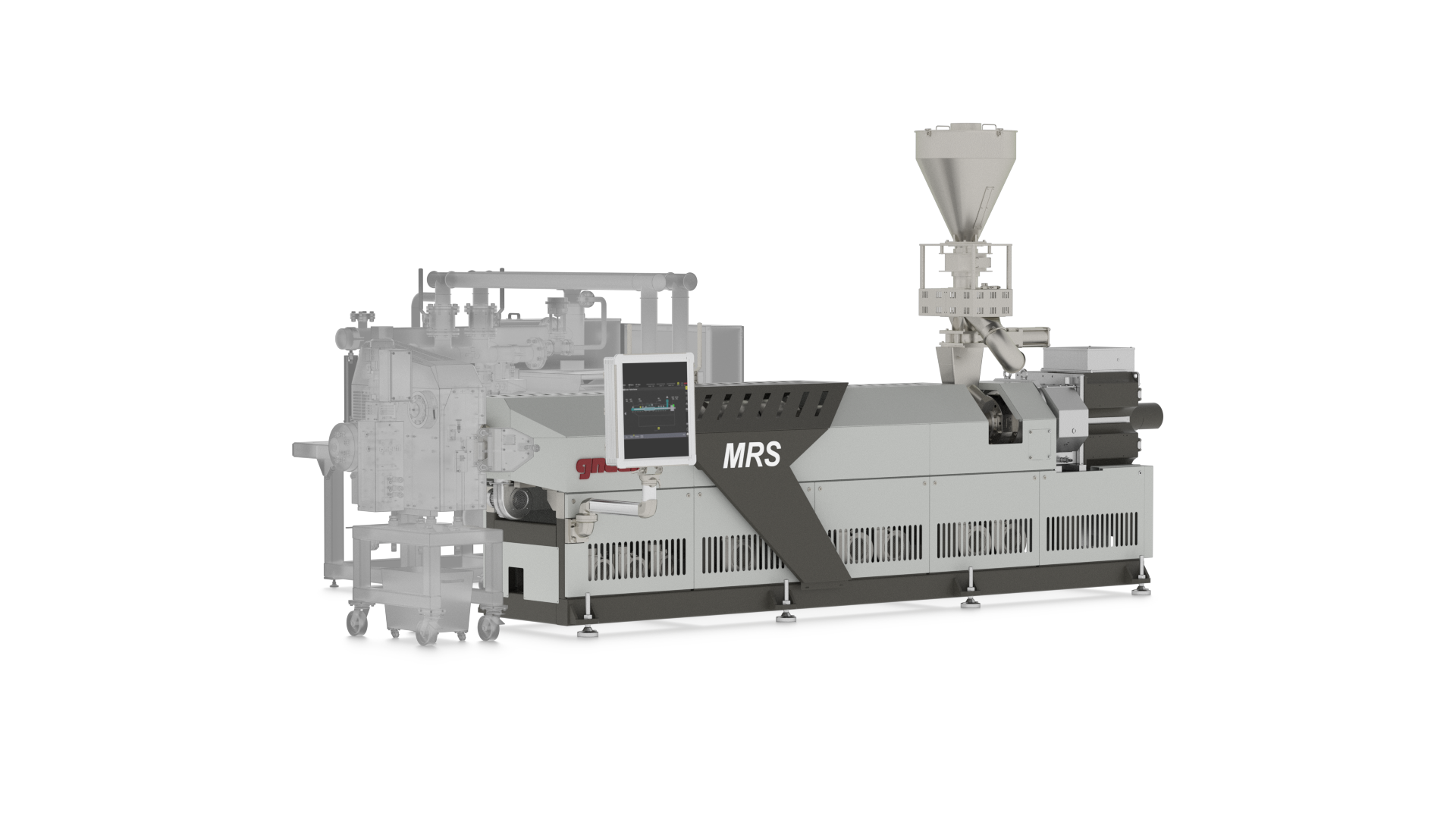

With its innovative OMNI recycling systems, Gneuss offers efficient solutions for today s and tomorrow s recycling requirements. The new OMNI recycling systems consist of a variety of machines from Gneuss portfolio, customized to a specific material and application, utilizing Gneuss established devolatilization and filtration technologies. The OMNI line is equipped with a 3C Rotary Feeder, an MRS Extrusion System, a fully automated RSFgenius melt Filtration System, a VIS online viscometer and downstream equipment. The OMNI Recycling Lines enables super clean recycling and are suitable for devolatilization, purification, decontamination, odour reduction, filtration and homogenization.

The MRS extrusion technology is based on conventional single-screw technology, but is equipped with a multi-screw degassing section. The degassing section of the patented process unit consists of an enlarged single screw drum with a series of satellite screws that rotate in the opposite direction of the extruder barrel, creating a very large melt surface area and ensuring very rapid surface exchange. This provides unprecedented melt phase degassing performance with minimal material stress. Multiple Letters of Non-Objection (LNOs) from the FDA, EFSA compliance and local approvals in Latin America confirm the high decontamination performance of the technology.

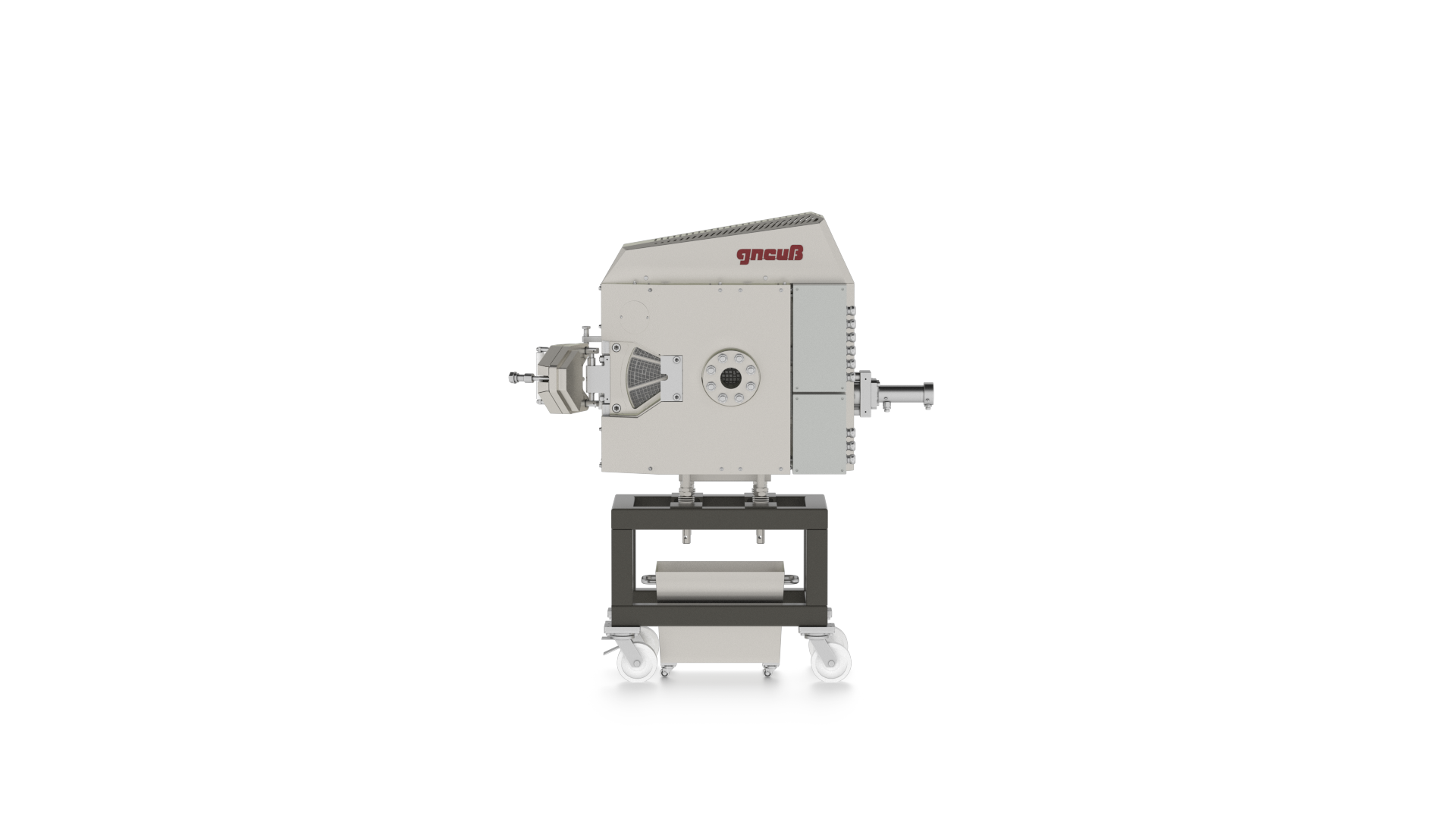

The highly efficient, self-cleaning Gneuss RSFgenius melt filtration system ensures that fine filtration is possible without pressure or flow disturbances and with minimal polymer losses, even at high contamination levels. The RSFgenius works with an integrated backflush system for self-cleaning of the screens for very demanding applications and highest quality requirements.

No represented companies found.

The company has no registered brand information.

TR

TR