| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

KAIFENG AONA PLASTIC EXTRUSION TOOLING CO.,LTD

No.11 South Section of Sanjie Street, Kaifeng, Henan Province / / / CHINA

|

Contact Info: +86 187 3999 5808

|

Hall: 11A

Stand: 11A-130A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Aona have been engaged in the mold industry for 26 years, and proficient in European and American section design and hardware installation; Design and manufacture of various extrusion moulds, such as doors and Windows /WPC/ wide sheet /PP/PE/PC/ASA; Workshop formulation design and optimization; Reduce workshop production costs while ensuring product quality; Deal with difficult problems in workshop production process; Workshop technical workers training, China s large high-end building materials factories often invite our comany people to train their technical workers; China s large high-end building materials factories are using my molds, while the molds are exported to the United States, Canada, Turkey, Egypt, India, Tanzania and other countries.

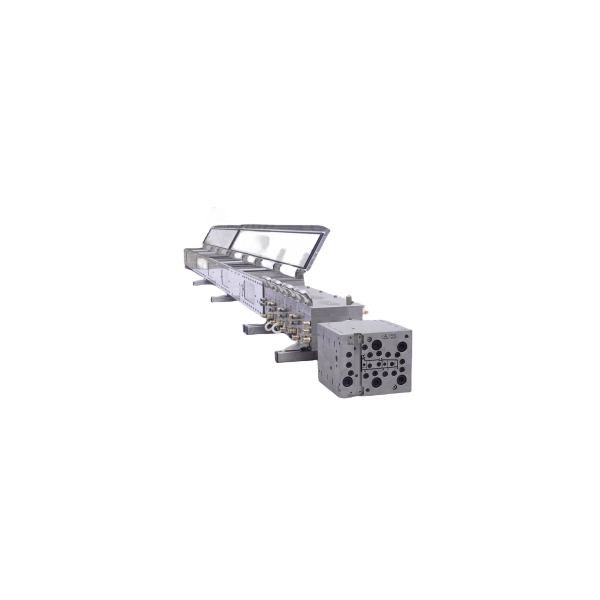

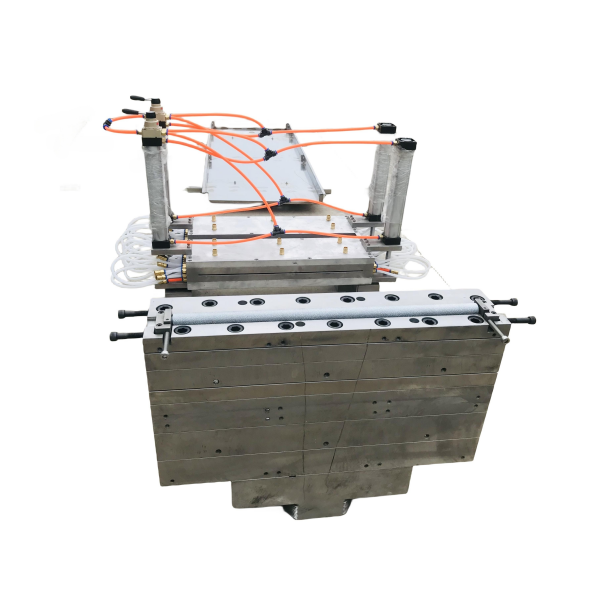

FEATURES AT A GLANCE Die head The extrusion die head design: Use the removable positioning device, making it easier to disassemble. Precise material flow control and stable extrusion. The hidden heating design has increased the brightness of the product surface. The special balance of the pressure holes has lowered the rejection rate. Calibrator The extrusion calibrator design: The automatically adjusting positioning key gives it a precise size The camber adjusting device ensures that the line is straight The inlet end is independent vacuum and shapes well Water tank Extrusion cooling design: Double vacuum system promotes the molding. The combination design of eddy current and spray makes it cools fast.. The self-adjusting water tank panels are easy to adjust. The stainless steel frame type system can prevent damage.The special influent distribution gives it a cooling balance.

It consists of die head, heating bands, calibrators and water tank. And it provides complete set of production process and technology transfer service. Die head The extrusion die head design: Use the removable positioning device, making it easier to disassemble. Precise material flow control and stable extrusion. The hidden heating design has increased the brightness of the product surface. The special balance of the pressure holes has lowered the rejection rate. Calibrator The extrusion calibrator design: The automatically adjusting positioning key gives it a precise size The camber adjusting device ensures that the line is straight The inlet end is independent vacuum and shapes well Water tank Extrusion cooling design: Double vacuum system promotes the molding. The combination design of eddy current and spray makes it cools fast.. The self-adjusting water tank panels are easy to adjust. The stainless steel frame type system can prevent damage.The special influent distribution gives it a cooling balance.

The difficulty design of foam WPC profile tooling lies in the pressure of die. Reasonable pressure design can ensure the profile density, foam unifor mity and production stability; Aona provides special toolings according to the formula characteristics: hard surface foam tooling, co-extrusion foam tooling, steel & plastic co- extrusion foam tooling, PVC &WPC foam tooling, PE &WPC Tooling, etc.

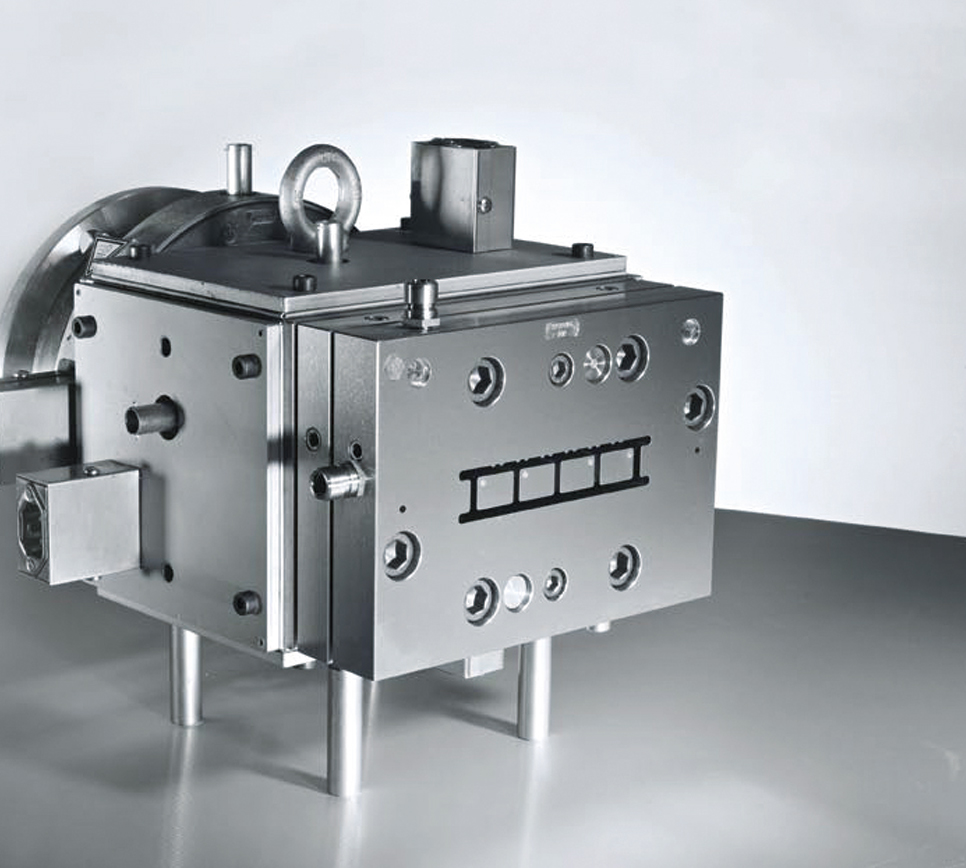

Aona adheres to the design concept of the pressure is consumed at the die lip outlet as much as possible . In this way, the designed runner always has pressure without material stagnation.The co-extrusion surfoce brightness is high and the production is stable. If there are special requirements for the surface brightness, flexible heating strip can be added at the die lip outlet to meet the personalized needs of customers.

Aona adheres to the design concept of the pressure is consumed at the die lip outlet as much as possible . In this way, the designed runner always has pressure without material stagnation.The co-extrusion surfoce brightness is high and the production is stable. If there are special requirements for the surface brightness, flexible heating strip can be added at the die lip outlet to meet the personalized needs of customers

No represented companies found.

The company has no registered brand information.

TR

TR